In complex piping systems, elbows are often seen as simple directional components. However, in reality, they play a critical role in maintaining the structural integrity and long-term performance of pipelines. SS 304 elbows, in particular, contribute significantly to reducing pipeline fatigue—an often overlooked but costly problem in industrial systems. Understanding their role can help engineers and project managers design safer, more durable pipelines.

Understanding Pipeline Fatigue

Pipeline fatigue occurs when piping systems are exposed to repeated stress cycles over time. These stresses may result from:

- Pressure fluctuations

- Temperature variations

- Flow-induced vibrations

- Mechanical movement or expansion

Over time, these repeated forces can cause microscopic cracks, leading to leaks, failures, or complete system shutdowns. Preventing fatigue is essential for maintaining safety and reducing maintenance costs.

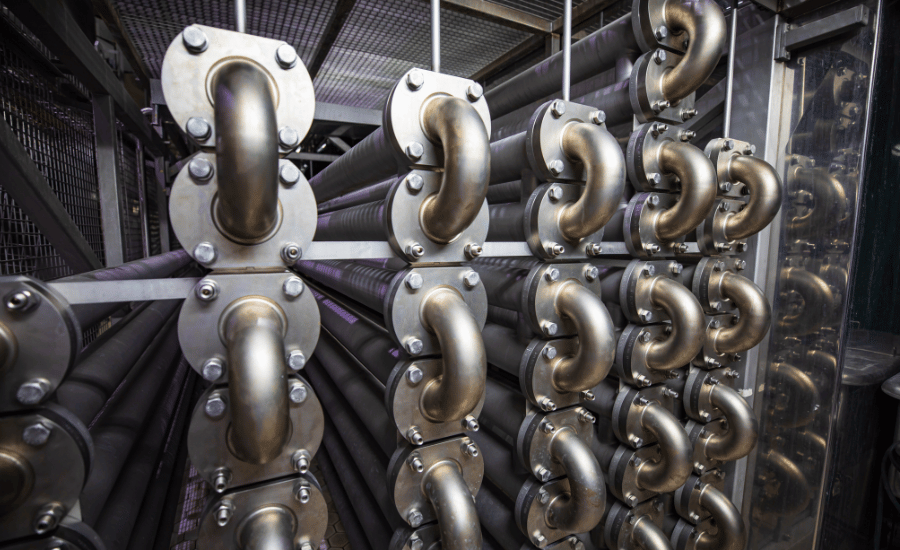

Why Elbows Are Critical Stress Points

Directional changes in pipelines naturally concentrate stress. Straight pipes distribute loads evenly, but elbows absorb:

- Flow momentum changes

- Thermal expansion forces

- Vibration-induced stress

Poorly designed or low-quality elbows can become weak points, accelerating fatigue damage. This is where the material and design quality of elbows become crucial.

The Advantage of SS 304 Material

Stainless Steel 304 is an austenitic stainless steel known for its excellent mechanical and corrosion-resistant properties.

Key Material Benefits:

- High tensile and yield strength

- Good ductility and flexibility

- Excellent resistance to oxidation and mild corrosion

- Stable performance across a wide temperature range

These properties allow SS 304 elbows to withstand cyclic loading without cracking, making them ideal for fatigue-prone applications.

How SS 304 Elbows Reduce Fatigue Stress.

- Smooth Stress Distribution

SS 304 elbows, especially long-radius designs, help distribute stress evenly across the bend. This reduces localized stress concentration that can initiate fatigue cracks.

- Vibration Dampening

The inherent ductility of SS 304 allows elbows to absorb vibrations caused by pumps, compressors, and turbulent flow. This dampening effect lowers the amplitude of cyclic stresses.

- Thermal Expansion Accommodation

Pipelines expand and contract with temperature changes. SS 304 elbows provide controlled flexibility, allowing movement without excessive strain on joints and welds.

- Resistance to Micro-Cracking

Unlike brittle materials, SS 304 resists micro-crack formation under repeated stress cycles, significantly extending the service life of the pipeline.

Design Factors That Enhance Fatigue Resistance

To maximize the fatigue-reducing benefits of SS 304 elbows, proper design is essential:

- Use long-radius elbows to minimize flow disturbance

- Ensure uniform wall thickness

- Follow ASTM and ASME standards

- Maintain high-quality welding and alignment

Even the best material can fail if installation and design practices are poor.

Common Applications Where Fatigue Resistance Matters

SS 304 elbows are widely used in:

- Chemical and pharmaceutical plants

- Food and beverage processing systems

- HVAC and steam pipelines

- Water treatment facilities

In these environments, continuous operation and cyclic stresses make fatigue resistance a top priority.

Conclusion

Though often overlooked, SS 304 elbows play a hidden yet vital role in preventing pipeline fatigue. Their material properties, combined with proper design and installation, help distribute stress, absorb vibrations, and accommodate thermal movement. By selecting high-quality SS 304 elbows, industries can significantly reduce fatigue-related failures, enhance safety, and extend the lifespan of their piping systems.